-

+86-20-3203 9088 mobile 18922125883 王先生Tel

-

astpower2014@163.comE-mail

-

+86-20-3203 9889Fax

Double pulse power supply is the latest generation of electroplating power supply, also known as flat wave / bidirectional pulse wave adjustable switching power supply. It rectifies power frequency alternating current into DC high-voltage power supply, generates low-voltage and large current power supply through high-frequency voltage transformation and high-frequency rectification, filters it into pure DC power supply through LC, and then sends it to an asymmetric full bridge transformation circuit (also known as chopping circuit) to generate a Artificial flat wave (i.e. pure DC) or bidirectional pulse square wave output.

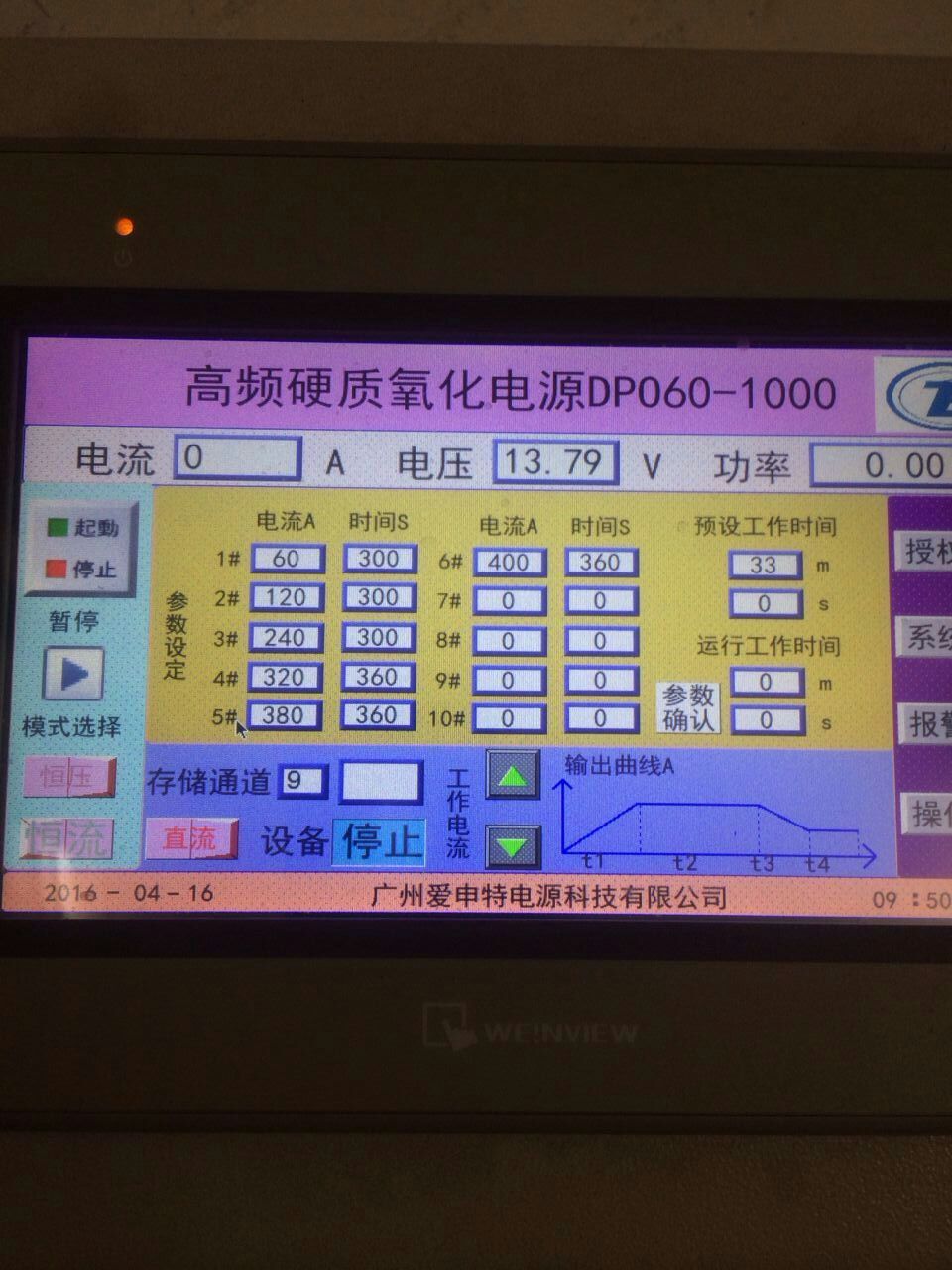

1. Dual pulse digital high-frequency power supply is a full-featured digital intelligent power supply, including the subsection setting of current and voltage, pulse frequency, duty cycle, parameter storage and other functions, which is suitable for the high demand process of products.

2. It is suitable for precious metal electroplating, PCB circuit board electroplating, semiconductor electroplating and other fields; gold plating, silver plating and other precious metals precision plating.

3. Strong reliability, ensure the safe operation of the equipment and reduce the occurrence of faults.

4. The protection function is comprehensive, including input overvoltage protection, undervoltage protection, short circuit protection, output overheating, overcurrent and phase loss protection, etc.

5. Small size, light weight, high efficiency, high control accuracy, saving power and use space.

6. High technical content, strong stability, improve work efficiency.

7. Digital display, intuitive.

8. The control mode can be divided into near control or remote control (PLC split type) and multi group control, which is easy to operate.

9. The box is made of zinc plate baking powder. The inner part of the equipment is designed as a sealed structure, which is acid and alkali resistant and corrosion-resistant, thus increasing the service life of the power supply products in the harsh environment.

Can be formulated according to customer requirements