-

+86-20-3203 9088 mobile 18922125883 王先生Tel

-

astpower2014@163.comE-mail

-

+86-20-3203 9889Fax

Establishment of IOT monitoring system for oxidation power supply

1、 Overall framework of IOT solution

2、 Function introduction of Internet of things

1. Remote transmission program: the program can be downloaded, uploaded and monitored remotely, and the on-site problems can be solved at home.

2. Data remote monitoring: the device data monitoring can be realized through the web page or mobile app to timely master the operation status of the device or modify the parameters.

3. Device alarm push: through SMS, wechat and voice to push the fault status of the device at the first time and grasp the operation status of the device in time.

4. Historical data query: you can query and save the historical data of the device, display it in the form of curve or table, and export it to the local.

5. Data statistics and analysis: it can count the energy consumption data and failure rate of the equipment, and carry out effective assessment and statistics on the equipment, so as to facilitate the analysis of different departments such as R & D, after-sales and sales.

6. Improve the efficiency of after-sales service: through the Internet of things platform, improve the efficiency of after-sales service.

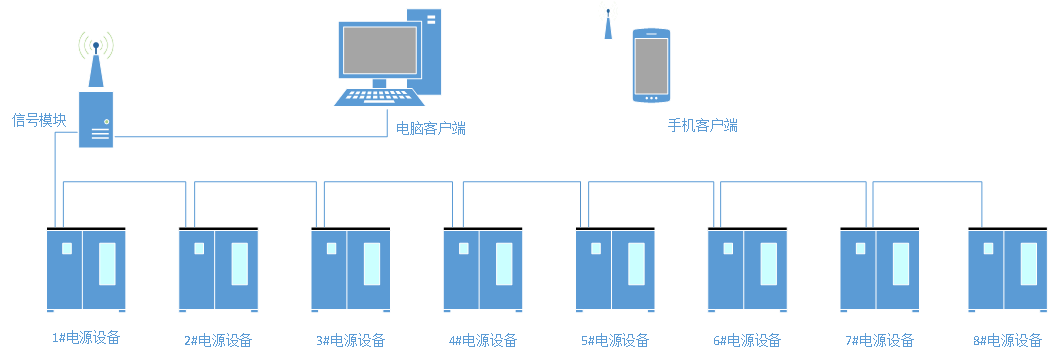

3、 Building the Internet of things framework of oxidation power supply

The IOT monitoring system based on oxidation power supply equipment includes real-time monitoring of output voltage, output current, equipment status and other information of each power supply equipment. It has the functions of data storage, data query, fault reminder and operation curve recording.

Introduction to Internet of things:

Online cloud configuration interface:

It supports adding multiple devices, customizing and modifying device icon and name, setting analog range conversion, one button control of regional devices, automatic recording of data, export curve and Excel data table.

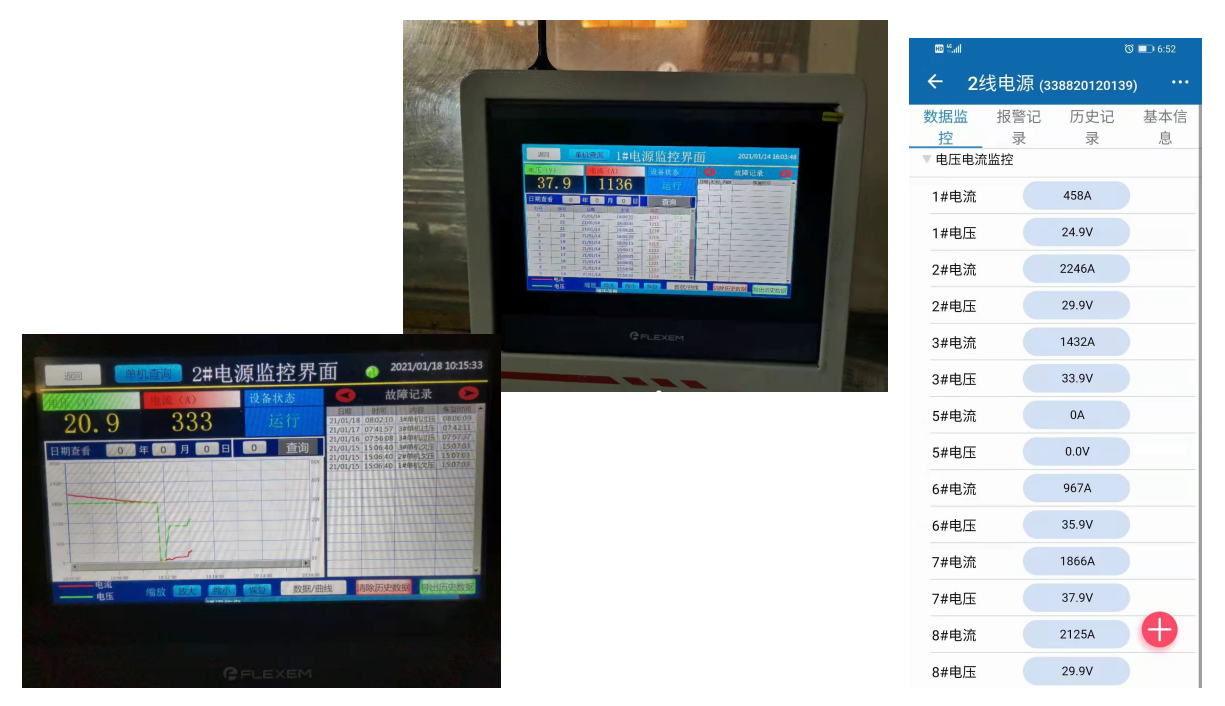

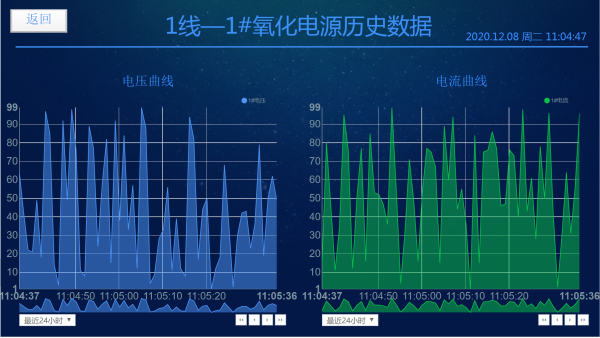

4、 Display of monitoring interface

Display of computer client interface

The main interface displays the current, voltage and equipment status of the current oxidation power supply equipment in real time. By clicking the button, you can enter the corresponding interface to query the historical data of oxidation power supply or enter other production lines, fault records, etc.

The history curve interface displays the history curve of voltage and current, and can query the data of nearly one year.

Mobile client interface display

Download mobile app. Monitor the status information of power supply equipment through mobile phone client, including historical data, fault alarm and fault recovery. Through SMS, wechat, voice and other ways, the device failure can be pushed at the first time, and the operation status of the device can be grasped in time.